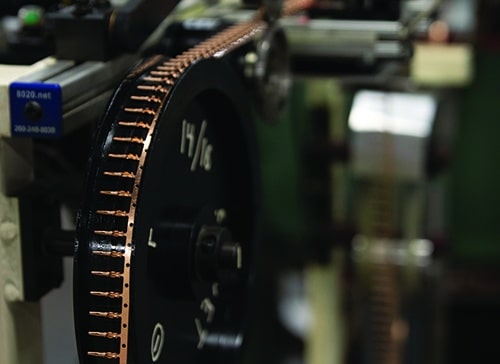

Global Manufacturing

Sigma has a global manufacturing footprint that includes 13 on-shore- near-shore, and off-shore facilities in the U.S., Mexico, and India. We also have third-party sourcing capabilities in China to help meet our customers’ needs.

U.S.-based Warehousing & Distribution

Our 180,000 square foot warehouse located in Garner, N.C., supports our global manufacturing by providing stocking and distribution capabilities that reduce lead times to as little as 5 days. The ability to integrate sales data to offer VMI programs and EDI capabilities for orders, invoices, and ASNs (Advanced Shipping Notices) provides customers with the data they need to manage their supply chains.

Industry-leading Service Levels

With U.S.-based warehousing and a continuous supply of inventory, Sigma is known for excellent fill rates and on-time deliveries. Our vertical integration and supply chain capabilities allow for a quicker response to demand fluctuations and increase the speed-to-market for your products.