Committed to Innovation

Sigma Engineered Solutions believes in purposeful innovation – the continual improvement and innovation of custom-designed and precision-made products and solutions. We partner with customers to reduce the lead time needed to design, develop, and build custom casting and precision metal stamping prototypes and products.

Developing the right solutions starts with understanding customer and market needs. We use this knowledge and expertise to create precision parts that meet and exceed expectations.

We're a Company of Problem Solvers

Developing the right solutions starts with understanding customer and market needs. We use this knowledge and expertise to create precision parts that meet and exceed expectations.

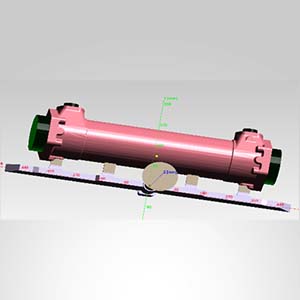

Case Study: Optimizing LED Heat Dissipation.

Using purposeful innovation to improve existing products.

Objective

A leading North American lighting manufacturer wanted to enhance their current heat sink design to improve overall heat transfer and reduce the weight of the product.

Solution

Sigma’s engineering team collaborated with the customer to develop multiple options that were evaluated using heat transfer and casting simulations. After a detailed Design for Manufacturability (DFM) study, Sigma created a product that reduced weight by 18% while also improving overall heat transfer efficiency.

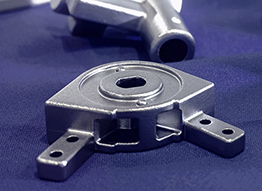

Case Study: Reducing Product Lead Time and Cost.

Challenging the status quo in product design.

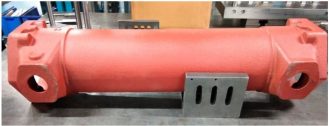

Objective

A leading North American customer wanted to increase the speed to market of an engine exhaust system without impacting the product’s performance.

Solution

Sigma’s engineering team worked closely with the customer to understand the functional requirements of the product. Using state-of-the-art casting simulation tools, Sigma developed a solution that combined various components into one piece to reduce the multiple operations, handling, and lead time, which thereby also reduced the cost of the product.

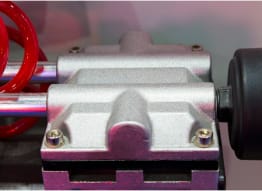

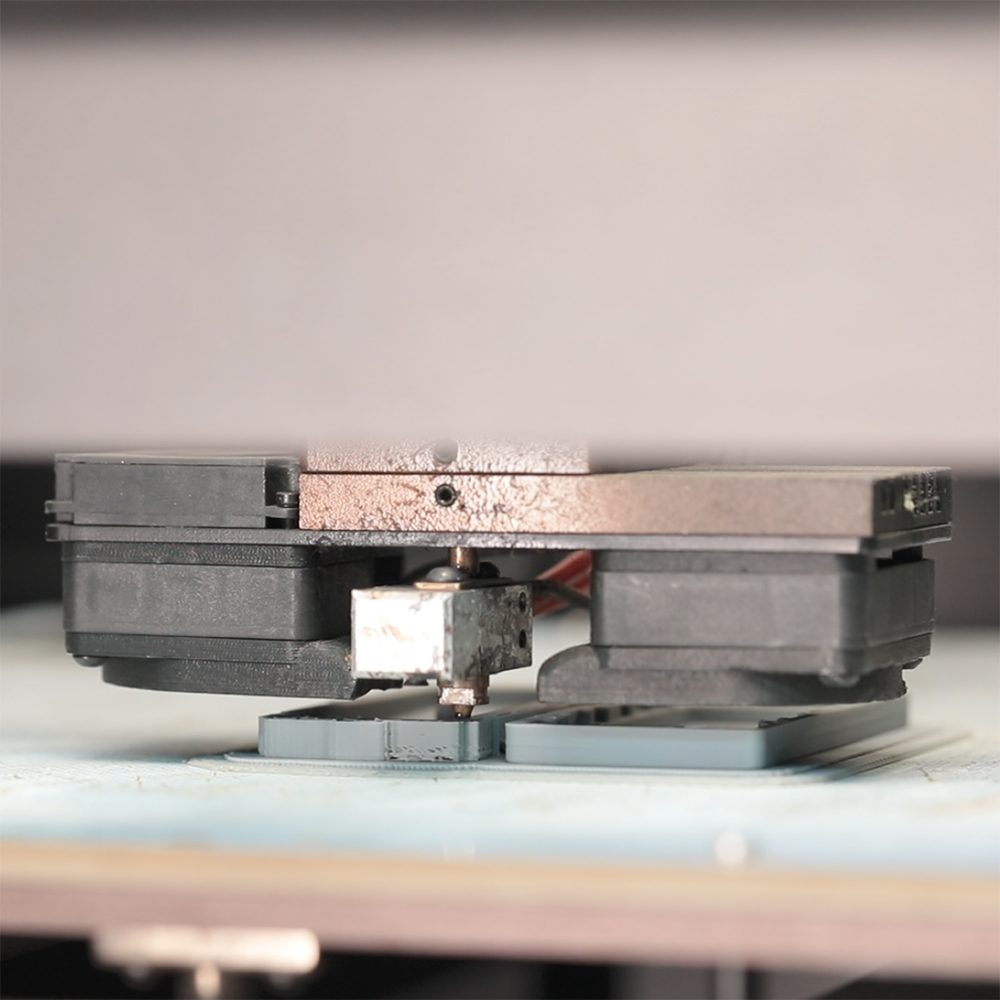

Case Study: Solving Customer Pain Points.

Innovation derived from end-user product use.

Objective

Develop an innovative solution to the difficulty faced by contractors when installing AC/MC cable in old work applications.

Solution

Sigma conducted end-user focus groups and created a Voice of the Customer brief to guide the product development process. Using a phase gate approach, Sigma developed the Double Snap Lock® Cut-In Connector, a patented, UL Certified product that helps save contractors time and money.