Achieving Engineering Excellence

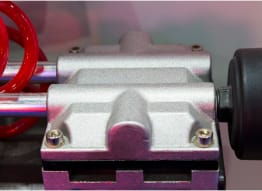

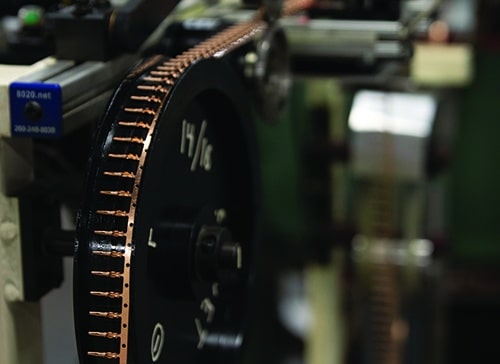

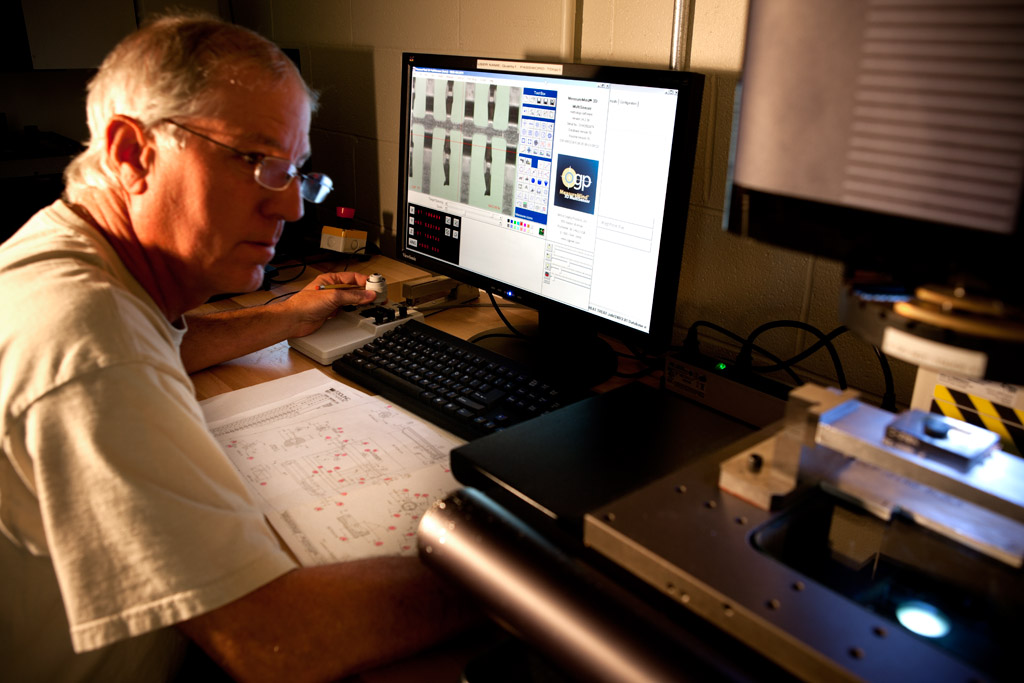

Sigma’s engineering expertise makes us the go-to partner for complex product characteristics and technical requirements. We design and produce parts with complex geometries, tight casting tolerances, and stringent porosity requirements. And our in-house product design and testing capabilities enable rapid product development with a single point of control.

We Like a Good Challenge

No matter the challenge, our more than 500 highly-skilled engineers will work with you to take your products from concept design through production.

Case Study: Reducing Product Carbon Footprint

Meeting customer needs for green and sustainable products.

Objective

A leading European-based energy technology and manufacturing company wanted to reduce the carbon footprint of a part without sacrificing quality, durability, or precision.

Solution

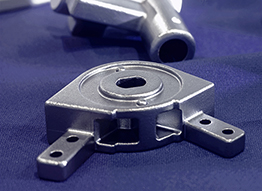

Sigma’s engineering team used state-of-the-art casting simulation tools to develop a solution that met all functional requirements for the part. Sigma converted the part from sand casting to die casting, which reduced the weight of the part by 25% and helped decrease the product’s carbon footprint.

Case Study: Improving Washing Machine Energy Rating

Meeting the demand for more sustainable appliances.

Objective

A leading appliance manufacturer wanted to improve the energy rating of their washing machines to appeal to sustainably-minded consumers.

Solution

Sigma’s engineering team used state-of-the-art casting simulation tools to identify multiple options for the washer drum spider that did not require changes to any mating parts. After an extensive design for manufacturability review and analysis, the final selected design reduced the weight of the spider by 33%, and parts were delivered for final testing within 10 weeks.

Case Study: Overcoming a Crowded Intellectual Property Landscape

Developing new products in a highly competitive product category.

Objective

A customer wanted to fill a gap in their weatherproof product portfolio with a new product that could be protected.

Solution

Sigma’s technical team collaborated with end users to identify product opportunities, and used lean design concepts to overcome a crowded patent landscape to develop a proprietary, patented portfolio of weatherproof while in-use covers.