Custom Tooling

Sigma is capable of designing and manufacturing tools in-house to reduce lead times, costs, and facilitate change management. Our state-of-the-art tool room produces more than 500 tools per year, and in-house tool production also ensures that your intellectual property is protected.

Applies to: Castings

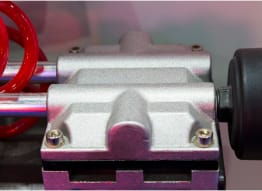

Precision Machining

Sigma uses state-of-the-art CNC as well as vertical and horizontal turning centers to machine intricate, tight-tolerance, and critical cast parts. These high-end machines provide a high level of repeatability and exceptionally smooth surface finishes.

Applies to: Castings

Surface Finishing

Our surface finishing processes include state-of-the-art in-house powder coating and liquid painting capabilities that are compliant with stringent UL requirements for extended outdoor product life and corrosion protection. Sigma also offers hot-dip galvanizing as well as zinc, tin, and silver plating.

Applies to: Castings

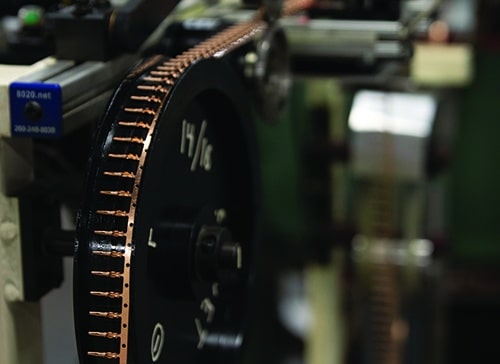

Special Purpose Machine Design & Development

Sigma's highly skilled engineering team can design, develop, and manufacture special purpose machines that substantially reduce project lead times. Our vertical integration ensures that all activities are kept in-house to provide complete protection of intellectual property.

Applies to: Castings

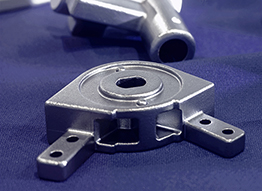

Tools & Dies

Our experienced Tool & Die makers increase your speed-to-market using our state-of-the-art tool room and in-house die build process. Created exclusively for building new dies, our tool room allows us to meet your custom requirements quickly and easily.

Applies to: Castings & Connectivity

Heat Treating

Our in-house heat treat ovens reduce lead time and provide cost flexibility while keeping quality control under one roof.

Applies to: Castings & Connectivity

Assembly

Sigma designs, maintains, and manufactures assembled components. We are a full-service facility that can become an integral part of your supply chain.

Applies to: Castings & Connectivity

Rapid Prototyping

When speed to market counts, Sigma’s Rapid Prototype services can create tangible products from your design in as little as 2-4 weeks. Using our flexible, low-volume prototyping platform, our experienced team will work with you from concept through production.

Applies to: Castings & Connectivity