Your Precision Metal Experts

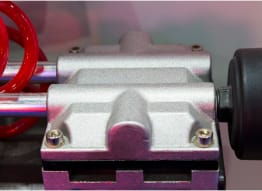

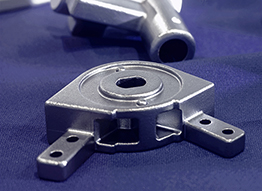

Sigma Engineered Solutions | Tooling Dynamics specializes in high-volume, precision metal stampings. We utilize 80 presses, ranging from 5 to 60 tons, to convert raw materials from various sizes and alloys into custom components for electronic connectors, sensors, and microprocessor chips.

We employ more than 25 journeyman tool and die makers with expertise to support the production of custom solutions down to 0.0001″ minimum tolerance.

35+ Years of Precision Metal Stamping Excellence

Supplying the highest quality precision metal stampings begins with engineering expertise. For over 35 years, Sigma Engineered Solutions | Tooling Dynamics has been serving the electroindustries, specializing in high volume, precision metal stampings.

Our innovative and experienced team provides complete in-house services from concept through production. We offer assistance in the design, prototyping, building, development, and all phases of manufacturing metal stampings.

As an ISO 9001 and TS 16949 registered supplier, quality is a part of everything we do.

.001″

We work with metals as thin as .001″ thick and under extremely tight tolerances.

2,000 SPM

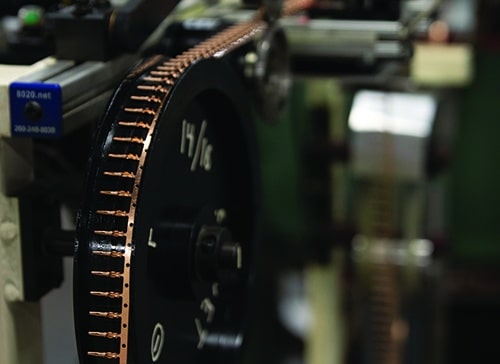

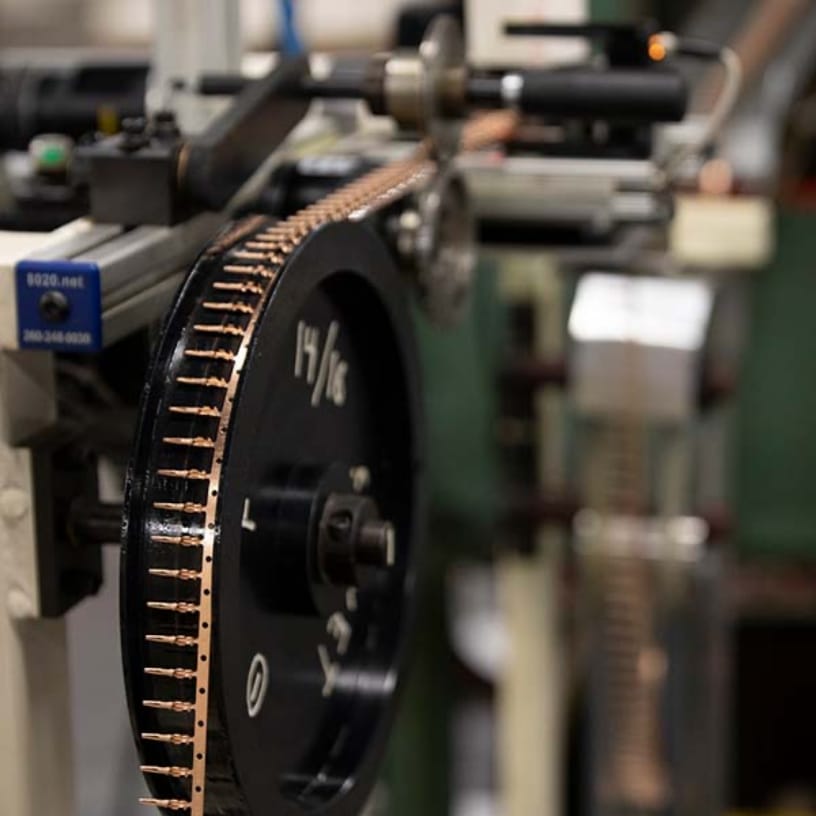

Capable of 2000 strokes per minute, our high-speed stamping process allows us to produce more than 1 billion parts each year.

CERTIFICATIONS AT A GLANCE

- ISO 9001

- IATF 16949

- AS9100-compliant

- ITAR registered

- Member of PMA (Precision Metalforming Association)

CAPABILITIES AT A GLANCE

- Staffed with over 20 Pennsylvania Journeyman Tool and Die makers.

- Over 80 presses ranging from 5 to 60 tons.

- Three shifts operating each day.

- Seven days a week production available.

- Reel to reel, bulk loose piece, or stacked production runs.

- 100 strokes per minute (SPM) up to 2000 SPM.

- A separate pressroom maintenance shop streamlines maintenance issues, keeps dies running, and keeps parts to specification.

Industries

Precision-engineered components to ensure performance and reliability in modern vehicles.

High-accuracy parts to support advanced connectivity and compact electronic devices.

Partner Services

Tool & Die Design/build/maintenance

Ensure optimal efficiency and longevity in production with expertly crafted tools and proactive maintenance, minimizing downtime and maximizing your output.

Prototyping

Accelerate your project timelines with rapid development of precision parts, helping you refine designs and ensure success before full-scale production.

Quality Control

Depend on rigorous quality checks to deliver flawless components, reducing errors and ensuring reliability in your final products.

Assembly

Simplify your production process with seamless integration of stamped parts, saving you time and ensuring consistency for complete, ready-to-use solutions.