Sigma Engineered Solutions – Tooling Dynamics is a world-class Contract Manufacturer with a global reach. Our core strength is Precision Metal Stamping, complemented by our specialized capabilities to deliver high-performance components with exceptional precision, speed, and scalability. We are your trusted partner, engineering the critical connections that power innovation.

Sigma Engineered Solutions – Tooling Dynamics is a world-class Contract Manufacturer with a global reach. Our core strength is Precision Metal Stamping, complemented by our specialized capabilities to deliver high-performance components with exceptional precision, speed, and scalability. We are your trusted partner, engineering the critical connections that power innovation.

Metal Stamping

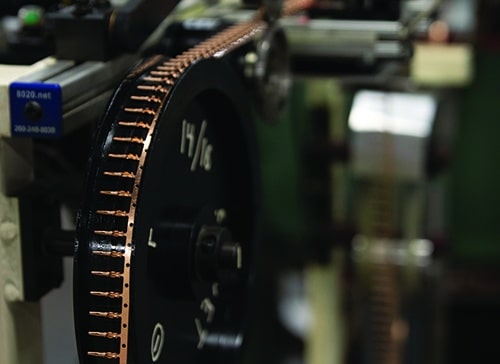

We specialize in high-speed, precision metal stampings tailored to your exact requirements. With 80 advanced presses, we transform diverse raw materials into high-quality custom metal stamped components, including electronic connectors, sensors, and microprocessor chips. Count on us to deliver solutions that work for you.

Swiss Machining

Whether you need miniature screws, contact pins for electronics components, micro-fasteners for medical applications, or other Swiss-type parts, count on us to handle your toughest jobs with comprehensive in-house production services and guaranteed on-time delivery.

ENGINEERING

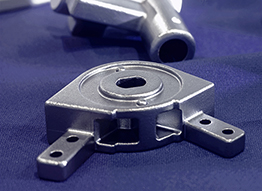

The design stage is essential in the metal stamping process, ensuring production viability and efficiency. By anticipating potential tooling modifications during this phase, we can minimize both time and cost over the course of the complete design cycle.

Our experienced and forward-thinking design team offers a full range of services from concept through production. We work closely with you to create tool designs that optimize costs and improve die maintenance, ultimately reducing your overall production expenses

In today’s competitive market, the ability to quickly bring your product to market is key to program success. Prototyping parts or specific components early allows you to identify potential issues and refine your design before moving into full-scale production, ultimately saving costs. Our flexible, low-volume prototyping services are tailored to meet your development schedule while helping you reduce expenses.

Tailored exclusively for new die creation, our state-of-the-art tool room is equipped to meet your needs with speed and precision. By distinctly separating the tool building and maintenance operations, we ensure a smooth and efficient workflow from design to production. Managing the entire die building process in-house allows us to shorten lead times, providing faster time to market for our clients

At Sigma Engineered Solutions | Tooling Dynamics, the job is not complete until the tool is qualified. With over 20 toolmakers on staff, we have the superior knowledge and engineering experience needed to meet your toughest requirements. We tackle the tough precision metal stamping jobs other metal stamping companies won’t pursue.

Production

At Sigma Engineered Solutions | Tooling Dynamics, we specialize in high-volume, precision metal stamping and Swiss screw machining. Our highest priority is customer satisfaction. With guaranteed on-time delivery and comprehensive in-house production capabilities, we offer the services you need and the quality and commitment you expect.

With over 80 presses, three shifts per day and seven-day-a-week capabilities, we are equipped to run millions of parts efficiently. We offer parts loose-piece or on-strip, use raw material arranged on coils or “pancaked”, and make parts ranging from microscopic to several inches in size.

Our toolmakers specialize in working with very thin gauge metals (as thin as .001” thick) and under extremely tight tolerances. Common production materials include beryllium copper, phosphorus bronze, stainless steel, copper, brass, cold rolled steel, and Mylar.

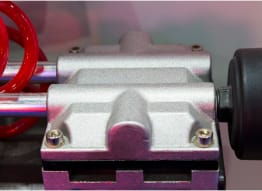

Automation

At Sigma Engineered Solutions | Tooling Dynamics, our automation team delivers innovative solutions to enhance quality, efficiency, and value for your business. We custom-build machinery for precise applications, with flexible designs to meet diverse needs. Our in-line visual inspection systems ensure only top-quality parts are shipped by monitoring critical dimensions and eliminating defects.

Automated packaging systems reduce costs by replacing manual processes with efficient, high-speed alternatives, while our custom assembly machines streamline production for complex products. We also upgrade existing equipment to boost performance, reliability, and adaptability.

Every project is tailored to your requirements, with a focus on cost-effective designs that optimize your production process and deliver unmatched results.

Quality Control

Our technically advanced stamping, machining, and inspection equipment are second to none. With 12 Keyence Vision Systems, 13 in-line PPT Vision Systems, and 4 OGP SmartScopes with laser depth capabilities, our customers’ parts undergo superior quality measures.

Quality control is a critical element of every process at SIgma Engineered Solutions | Tooling Dynamics. From the arrival of raw materials at our dock to the delivery of finished parts to our customers, our quality control department is an essential participant at all stages in metal stamping engineering and production.

Customers’ specifications and dimensions are constantly tracked and monitored throughout the production process. To enhance our inspection capabilities, we use a number of quality control programs such as Statistical Process Control (SPC) and chart PPKs and CPKs for critical dimensions.

All customers receive a first article inspection report (on all new programs), a copy of our production inspection plan, and documented workmanship specifications on each part with visual aids available upon request for your retention.

Shipping

Our on-site warehouse ships to customers worldwide. We offer consignment and Kan-Ban services both internally and off-site at customer locations.

Speed & Quality You Can Count On

Our skilled Tool & Die makers can increase your speed-to-market by leveraging our state-of-the-art tool room and in-house die construction. Additionally, we offer heat treating, assembly, and rapid prototyping, bringing your designs to live to market in minimal time. As a longtime ISO 9001 and IATF 16949 certified supplier, Sigma Engineered Solutions | Tooling Dynamics is dedicated to delivering quality and reliability at every step!

.001″

We work with metals as thin as .001″ thick and under extremely tight tolerances.

2,000 SPM

Capable of 2000 strokes per minute, our high-speed stamping process allows us to produce more than 1 billion parts each year.

Industries

Precision-engineered components to ensure performance and reliability in modern vehicles.

High-accuracy parts to support advanced connectivity and compact electronic devices.

Partner Services

Tool & Die Design/build/maintenance

Ensure optimal efficiency and longevity in production with expertly crafted tools and proactive maintenance, minimizing downtime and maximizing your output.

Prototyping

Accelerate your project timelines with rapid development of precision parts, helping you refine designs and ensure success before full-scale production.

Quality Control

Depend on rigorous quality checks to deliver flawless components, reducing errors and ensuring reliability in your final products.

Assembly

Simplify your production process with seamless integration of stamped parts, saving you time and ensuring consistency for complete, ready-to-use solutions.