Serving the Electronics & Telecom Markets with Precision Parts

We support the electronics and telecom industries with high-quality, precision parts produced by Sigma Connectivity and Sigma Castings.

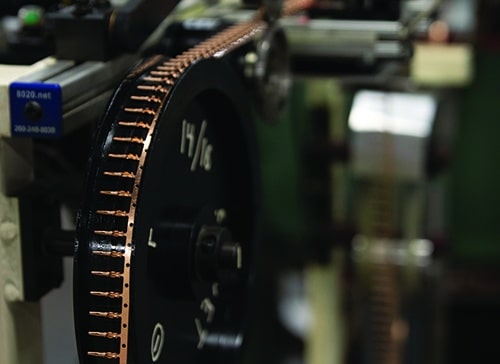

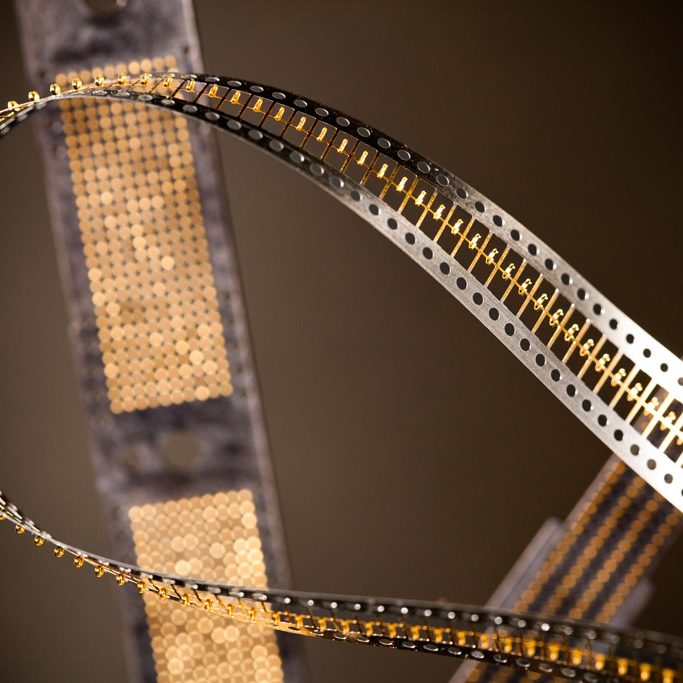

Electronic sensors and connectors produced by Sigma Connectivity help make products faster and more efficient and can be found in next-generation wireless infrastructure, mobile devices, gaming systems, graphic processing units, high-resolution screens, interactive touchscreens, and advanced connectivity solutions for automobiles. Sigma Connectivity specializes in high volume, precision metal stamping, with expertise in working with very thin gauge metals under extremely tight tolerances – many of our stampings are one-half to one-quarter the thickness of a piece of hair.

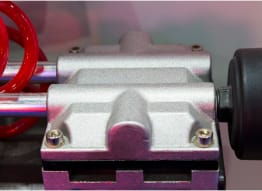

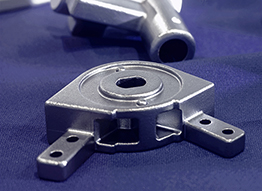

Sigma Castings produces strong, accurate parts used throughout the telecom industry. Our housings and covers can be found in base stations for cell towers, and we eliminate impurities in the casting process that can lead to distortion in transmission. Our global supply chain solutions provide you with a reliable source of products, and we can manufacture customized parts made to your specifications.

Sigma Engineered Solutions can assist you in the design, prototyping, building, development, and all phases of manufacturing your custom parts. We also offer automated quality control to check critical dimensions and tolerances

We make precise sensors and connectors that meet the most exacting tolerances.

Featured Product: Digital Meter Cover

Additional Product Examples

Antenna Parts

Camera Arms

Home Automation Units

LGA Contacts

Our Services

Sigma offers a number of services that can help with your Electronic product needs.