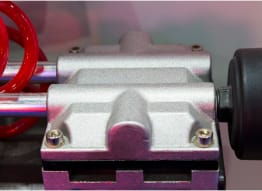

Die Casting Process

The die casting process uses large amounts of pressure to push molten metal through a pre-formed mold. Die casting produces precise, highly accurate, and reliable parts.

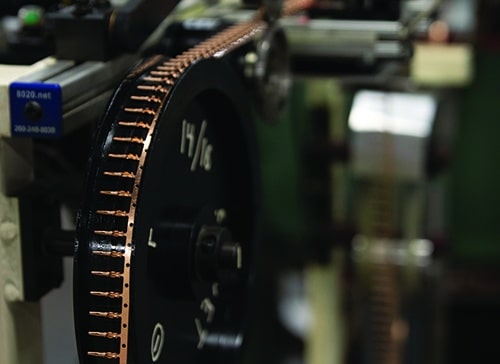

Die Casting Capabilities

Sigma Castings is one of the largest manufacturers of Zamak castings in the world, The company also has state-of-the-art aluminum and zinc die-casting equipment that can produce complex value-added sub-assembled components.

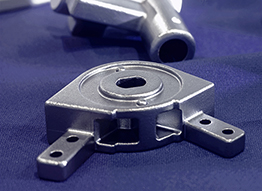

Die Casting Products

Our die cast products can be used in a wide range of applications, including electrical, automotive, appliances, power tools, telecom, lighting and marine.

Advantages

Die casting can produce products with a high degree of surface detail, excellent dimensional accuracy, and very thin walls. Die cast components can be produced in high volume with relatively little tooling or machining, and can create finished parts with curved or seamless surfaces. Sigma Castings is capable of producing parts from .1 ounce to 16 pounds.