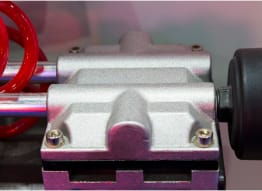

Gravity Die Casting Process

Like high-pressure die casting, a molten metal alloy is poured into a preformed mold. True to its name, the molten metal is poured into the mold from above, filling the mold from the bottom up using gravitational force.

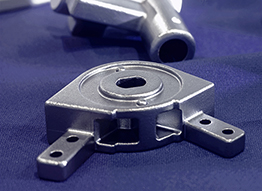

Gravity Die Casting Capabilities

Ideal metal alloys include aluminum, zinc, magnesium, lead, tin, or copper.

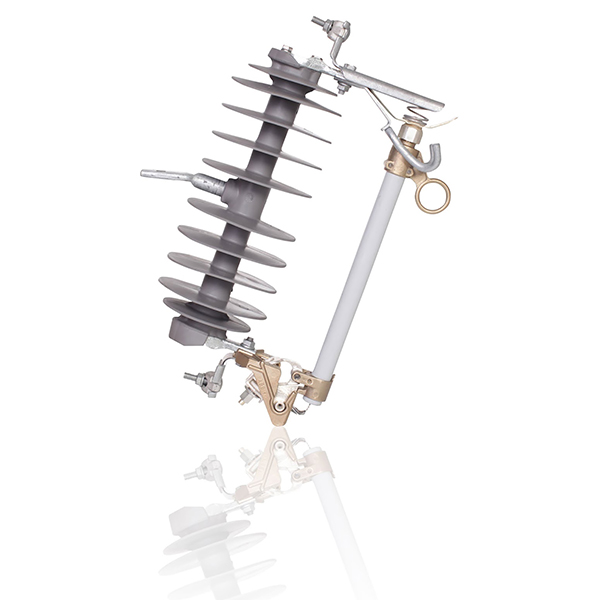

Gravity Die Casting Applications

Sigma produces high-quality bronze gravity die cast structural components for the power distribution and transmission market.

Advantages

The slower speed in which molten metal enters the mold means that less air will be trapped in the casting. Since gravity die casting relies on gravity to fill a mold, the process is slower than pressure die casting and therefore it is less efficient on long production runs.