Multiple Casting Options to Meet Your Needs

At Sigma, we excel in bringing your ideas to life with our diverse casting solutions. Whether you need intricate details or large-scale production, our expertise covers a wide range of metals. We pride ourselves on our in-house tooling and specialized machine design, which allow us to handle any project with confidence. With 13 locations around the globe, we are equipped to create custom solutions tailored to your unique needs. Our goal is to deliver products that align perfectly with your vision.

Our Casting Processes

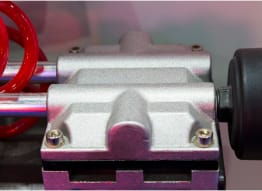

High Pressure Die Casting

Die casting is the process of injecting a molten metal alloy into a die to form a die cast part. Sigma Castings has state-of-the-art aluminum and zinc die-casting equipment that can produce complex value-added sub-assembled components.

Sand Casting

In the sand casting process, molten metal is poured into molds made of compressed or compacted sand. It is one of the most widely used casting methods and it is ideal for products with complex shapes and inner cavities.

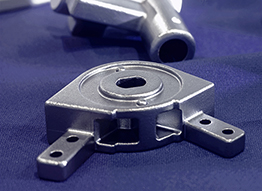

Investment Casting

Investment casting is an industrial process based on lost wax casting. Investment casting creates products with tight dimensional and geometric accuracy and is ideal for near-net-shaped products with complex shapes and high precision requirements.

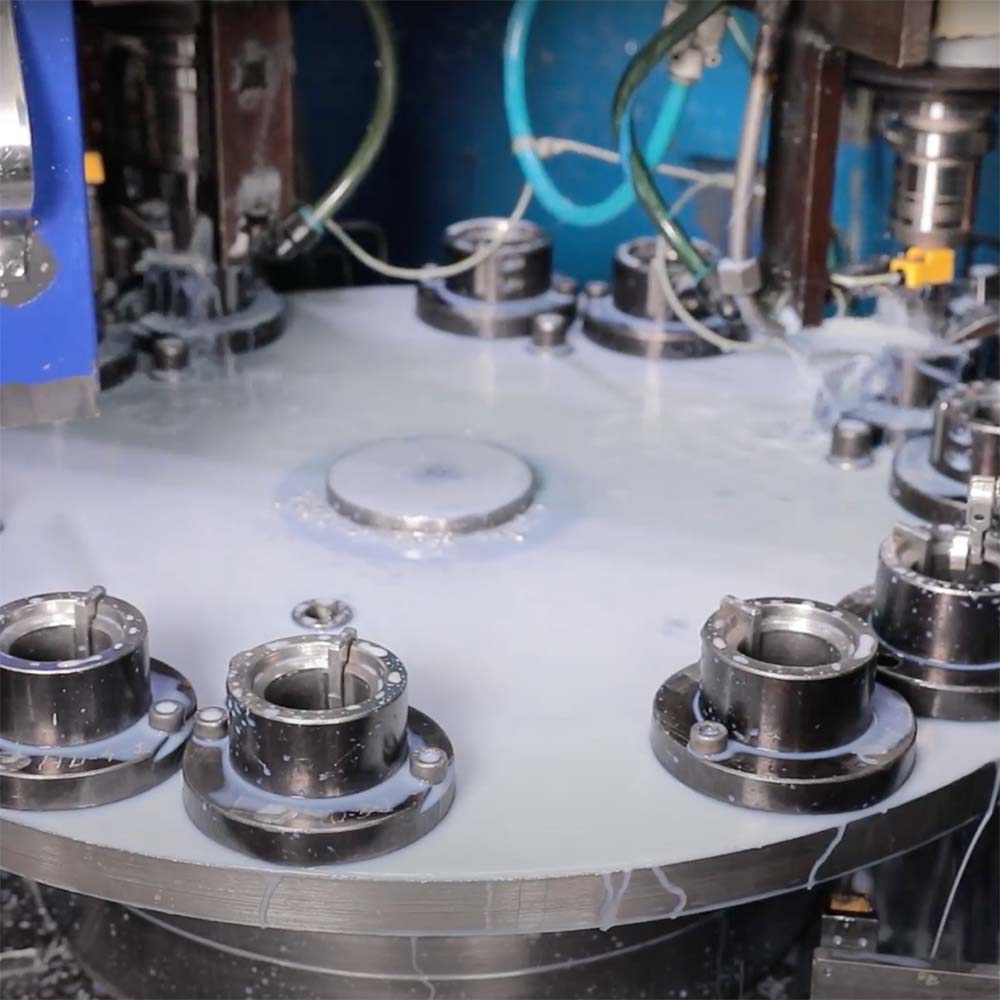

Gravity Die Casting

In the gravity die casting process, metals with high melting temperature are poured into a preformed mold from above, filling the mold from the bottom up using gravitational force. It is ideal for products that require heat treating of the casting.

Partner Services

Sigma offers a number of services that can help with your Connectivity product needs.